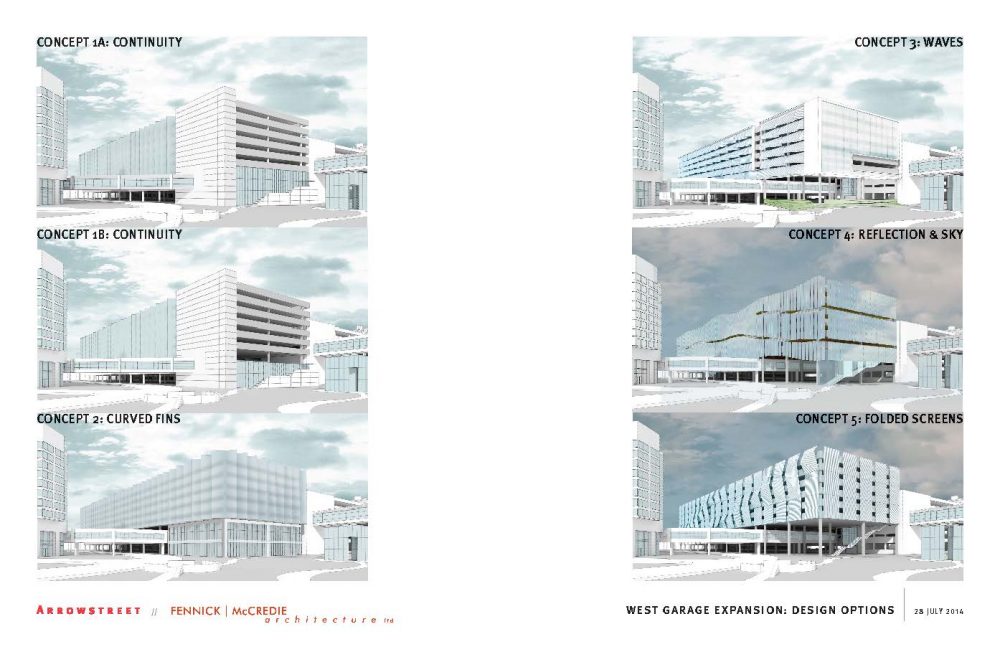

The Massachusetts Port Authority (Massport) has big plans for Boston’s Logan International Airport, ranging from the modernization of Terminal E to the expansion of adjacent runways. In 2016, as part of these modernization efforts, Boston-firm Arrowstreet delivered a dynamic expansion of its West Garage featuring a kinetic aluminum facade.

Located adjacent to the I-90 and the Logan Airport 9/11 Memorial, the site is highly visible to the nearly 30 million passengers that pass through the airport annually. The objective of the project? To deliver an easily assembled second skin capable of obscuring the structure’s utilitarian purposes while simultaneously providing outward views from within. According to Arrowstreet Principal David Bois: “The movement of air currents, a critical component of aviation, provided inspiration to the design team, the individual movement of the panels provides a visualization of air movement and a constantly changing facade.”

Faced with a tight schedule, Arrowstreet recognized that the screen wall had to be fastened to the garage in a straightforward and adaptable fashion. The facade system is composed of 353, 11-by-5-foot panels that are Z-clipped to individual galvanized hangars, which are epoxy bolted to the precast concrete garage. Because of the Z-clips, individual panels can be rapidly removed from the overall structure for ongoing maintenance and inspection.

The kinetic element is composed of six-inch curved aluminum squares that can move in the breeze. The 50,000 individual flappers are connected to the frame by a series of stainless steel rods and nylon spacers that allow the flappers to spin with the least amount of friction possible. With minimal resistance, the panels move even during minimal wind conditions.

Below the moving aluminum flaps, Arrowhead placed tiered rows of multicolored fins to provide the structure further luster.

The design concept was modeled in Rhino and Revit, and the team was able to simulate the kinetic movements of the system for various panel sizes. After Arrowstreet tested a broad range of panel sizes, the firm exported the models for custom fabrication by exterior specialists, Extech. Linetec finished the flappers with their Class I clear anodize.

Prior to installation, Arrowstreet installed a full-scale mockup onsite to test installation procedure, functionality, and resiliency. Furthermore, a section of panels and flappers were transported to Intertek’s architectural testing facility to undergo hurricane simulations to evaluate the resiliency of the fabricated prototype during extreme weather conditions.