Behnisch Architekten’s AGORA Pôle de Recherche Sur le Cancer in Lausanne, Switzerland, overlooks the historic core of the centuries-old city from a prominent ridgeline within the city center, contorting itself into multiple planes of curtain wall shaded by a continuous band of aluminum apertures.

As an approximately 240,000-square-foot cancer research institute, the complex’s program calls for easily navigable and well-illuminated corridors linking offices and research spaces for hundreds of practitioners. Additionally, the central meeting place of the facility—dubbed “AGORA” in homage to the ancient Greek sphere of public assembly—is topped with a semi-translucent ETFE canopy.

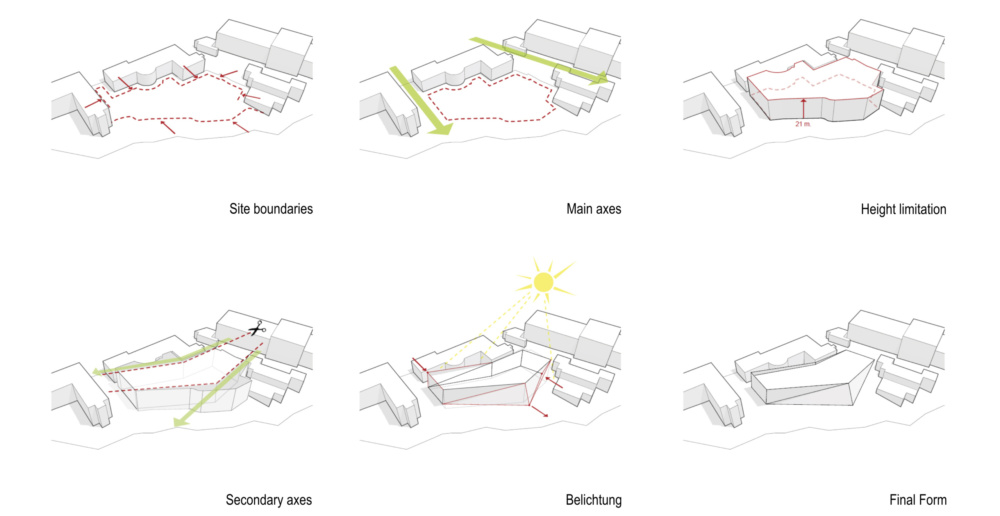

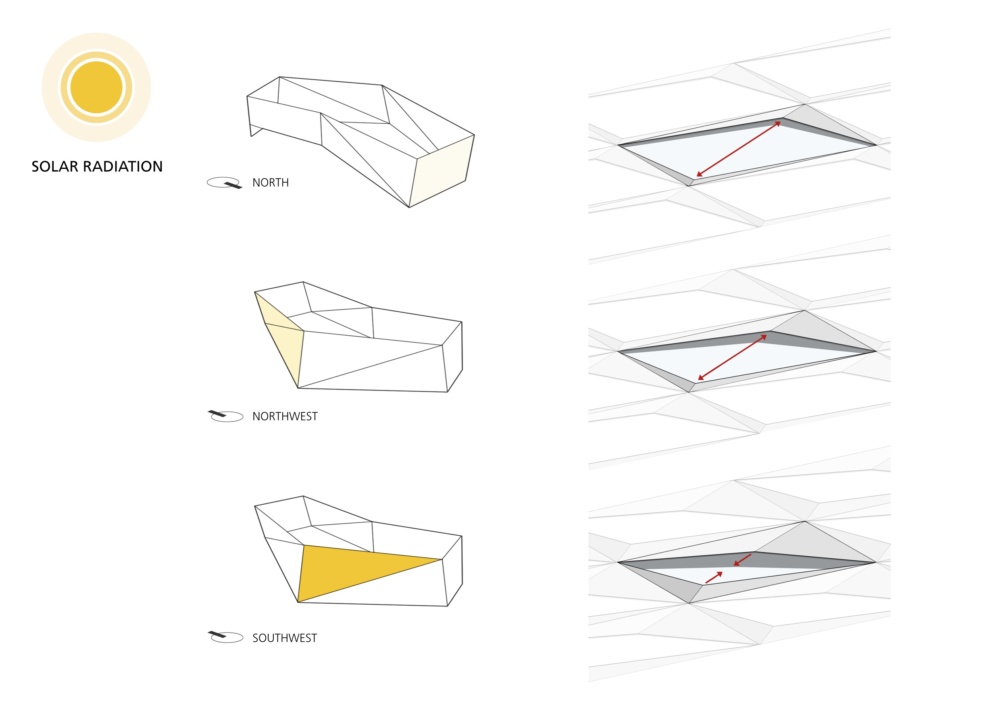

“AGORA was our first effort at developing a stationary, responsive solar shading system, which developed out of the original competition design,” said Behnisch Partner Robert Matthew Noblett. “The concept is essentially moving the sophisticated technology involved in responding to solar angles that change throughout the day and year and deploying it on the design side in the form of parametric modeling and fabrication, optimizing shading elements according to orientation and season.”

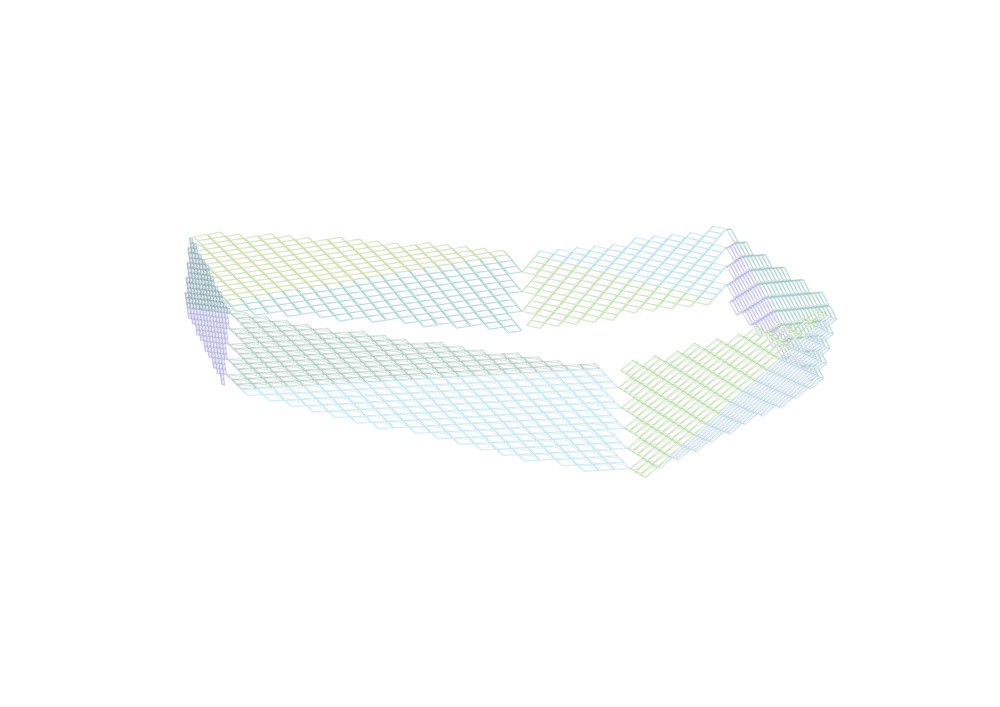

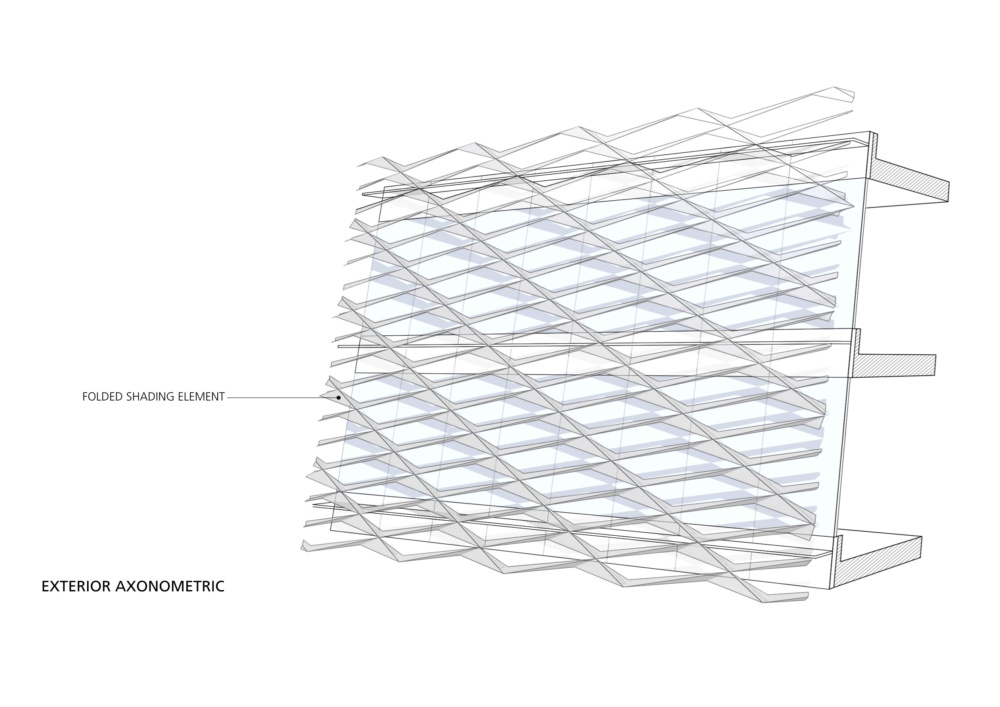

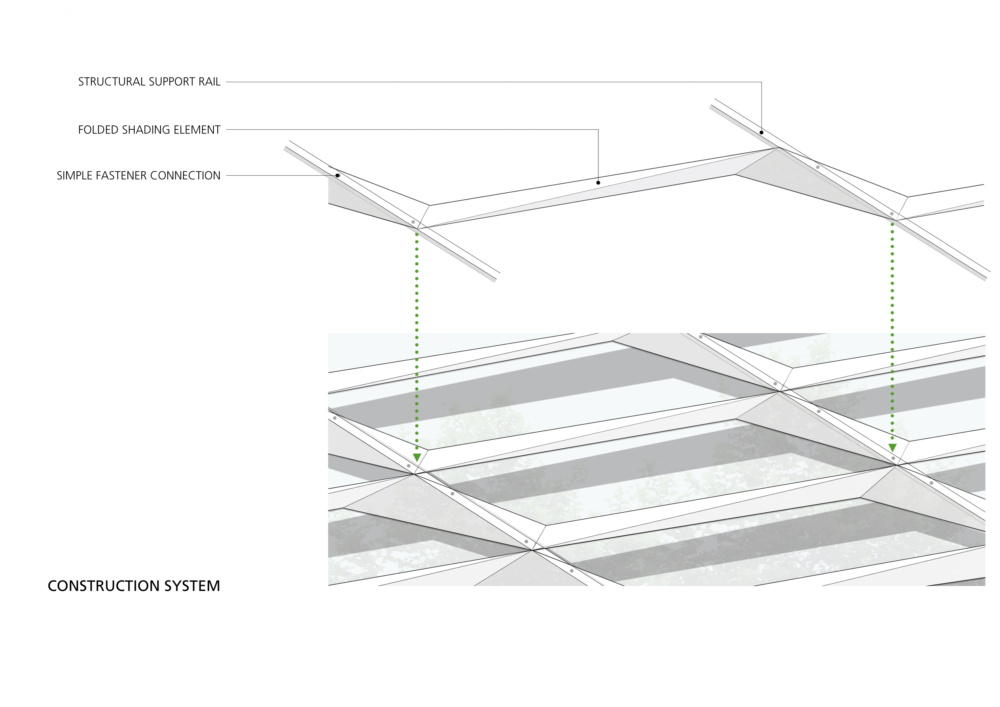

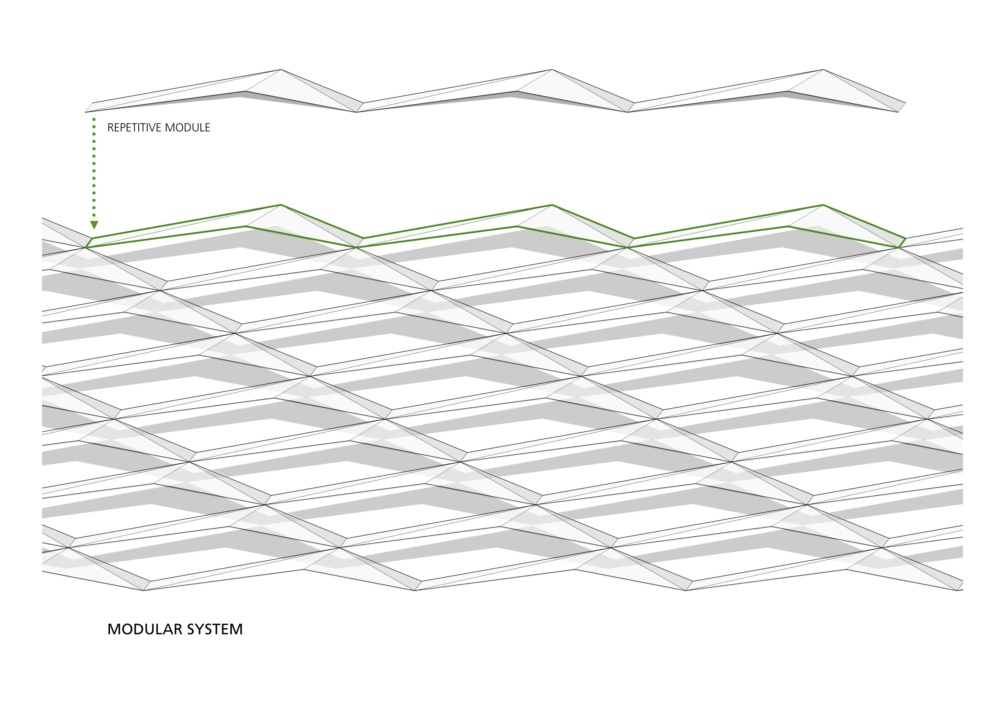

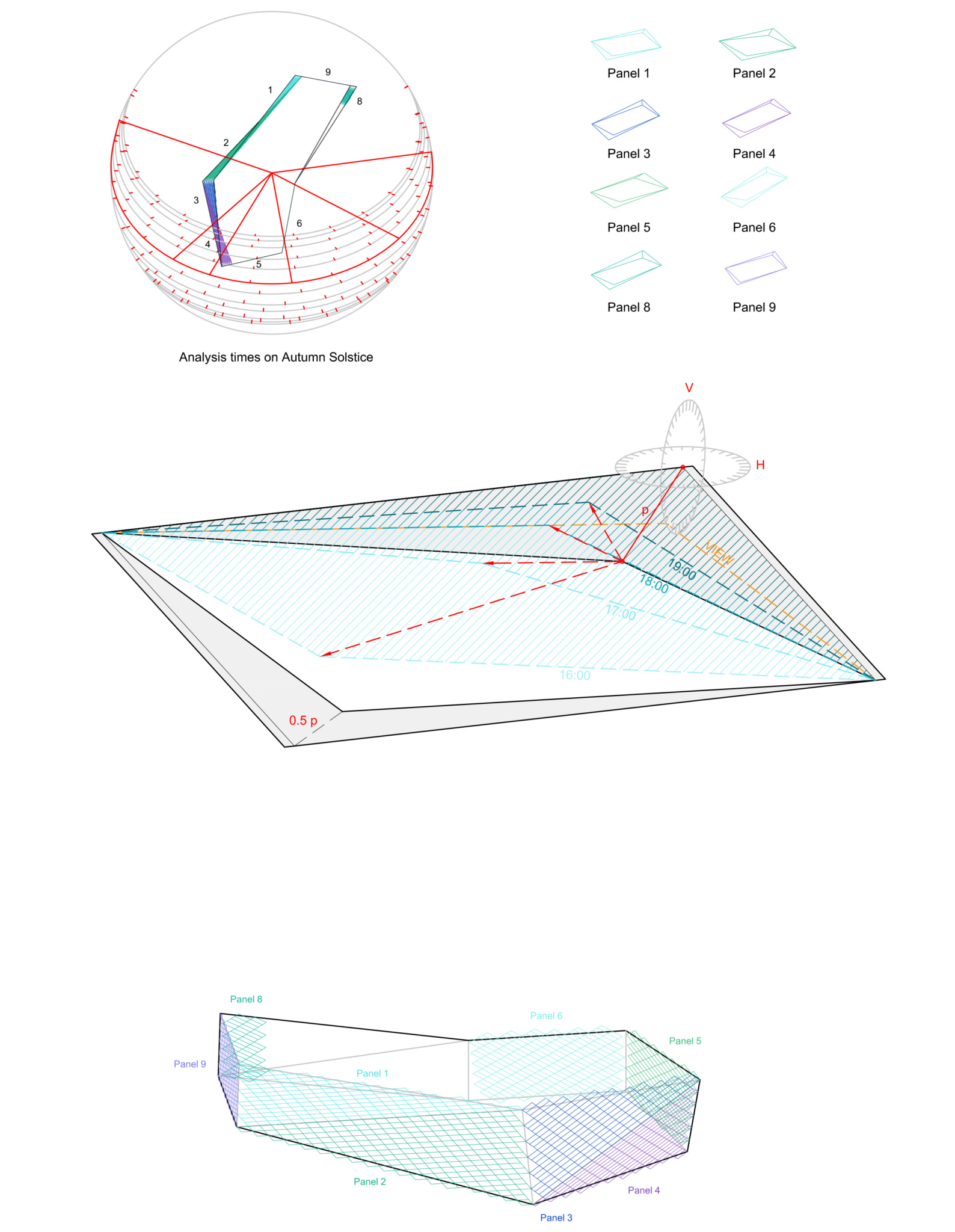

The second skin of the building consists of a continuous aluminum screen that runs across the underlying glazed facade. Each of the facade’s nine distinct planes is shaded with a unique variation of the screen; the skin on the north has relatively large openings while that on the south is more constrained. The panels consist of two folded aluminum pieces joined together to resist bending.

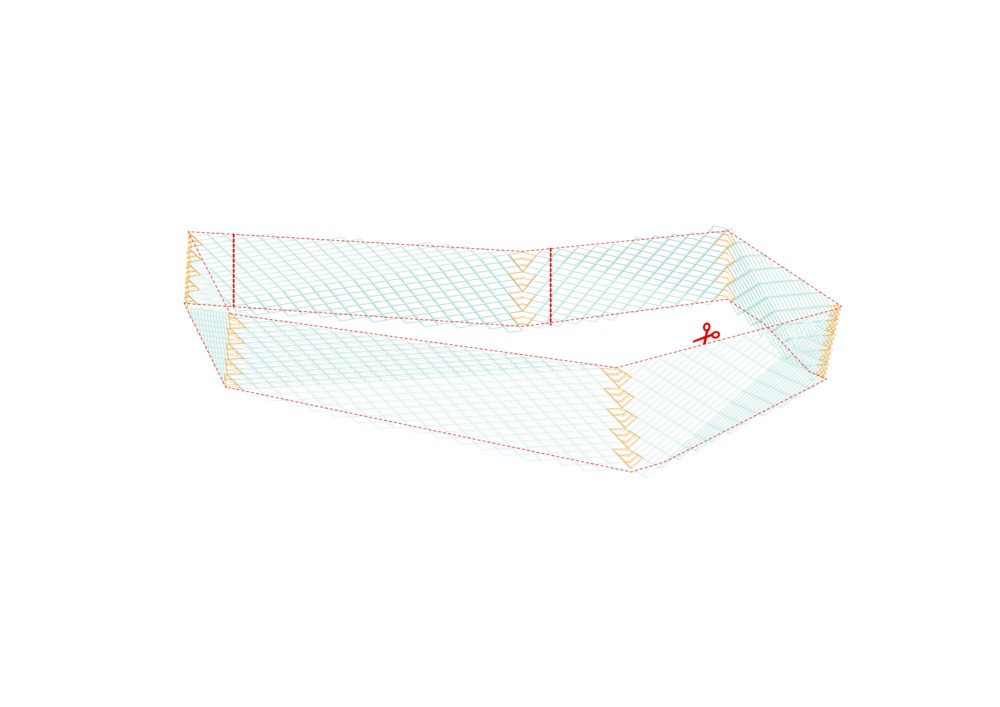

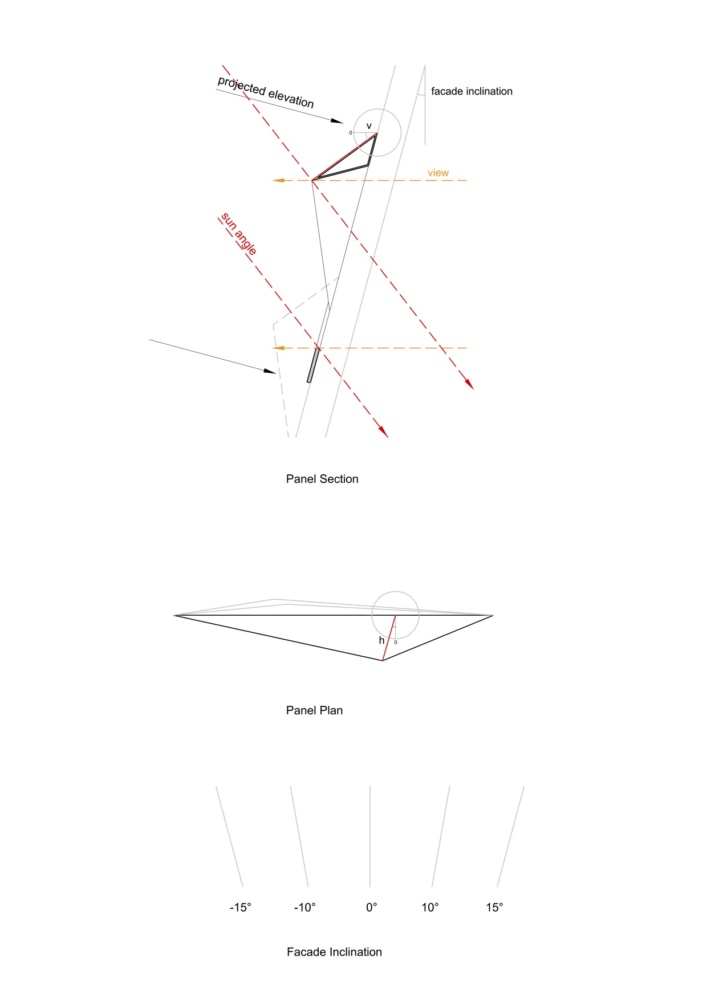

For the shading requirements of the building, Behnisch Architekten developed a set of parametric guidelines for Rhino, Grasshopper, and AutoCAD. The length of the “P” line, the protruding-perforated aluminum flap, was determined by the “V” plane perpendicular to the facade, and the “H” plane parallel to the facade. After producing scores of digital simulations for sun and heat protection, light enhancement and glare, the design team built multiple physical models that were tested under artificial lighting.

“The optimization of the facade is controlled both by the aperture and its orientation, which respond to the orientation of the glass surface and its type of glass,” said the design team. “The same solar performance can be achieved for every given angle of the sun with an array of different geometries that offer all the different view openings and qualities.”

The second skin is located approximately 2.6 feet from the inner facade, allowing for the insertion of a maintenance catwalk and over half-a-foot of space for the secondary structure supporting the shading panels. The secondary structure is composed of a series of diagonal steel rails running parallel to each other. Every short end of the panels are connected to the steel rails via simple fastener connections. Armatures extending from the inner facade support both the catwalk and the steel rail system.

According to the design team, one of the greatest challenges of the project was the connection of the bands of aluminum apertures across nine unique facade planes. To maintain the visual continuity of the second skin, Behnisch Architekten collaborated with manufacturer and installer Sottas SA to produce a unique seam of aluminum pieces for each corner.

In the coming years, Behnisch will monitor the performance of the complex’s enclosure system. Lessons learned from the study of the structure will inform the design of similar systems for ongoing projects such as Harvard’s School of Engineering an Applied Sciences and the ARENA HQ in Germany.