While gothic revival architecture can be found on nearly any campus, rarely are these traditional exteriors extolled for their energy efficiency. However, the residential E. Bronson Ingram College building showcases the historic character of the treasured Vanderbilt University campus while also achieving LEED Gold. Located in Nashville, the campus holds an eclectic blend of late 19th and early 20th-century architecture, including the iconic Kirkland Hall, which was completed in 1875.

- Waterproofing & Envelope

Consultant

Mariani Metals - Architects

David M. Schwartz Architects

HASTINGS Architecture - Masonry Contractor

Kelly Construction - Structural Engineer

Blackwell Engineer - Construction Manager

R.C. Mathews Contractor - Location

Nashville, TN - Date of

Completion

2018 - System

modular brick, limestone, and crab orchard stone - Products

Indiana limestone by Bybee Stone Co. Inc.

Crab Orchard stone by Rocky Ridge Stone Company

Clay brick by Alley Cassetty Companies, Inc.

Ludowici clay tiles

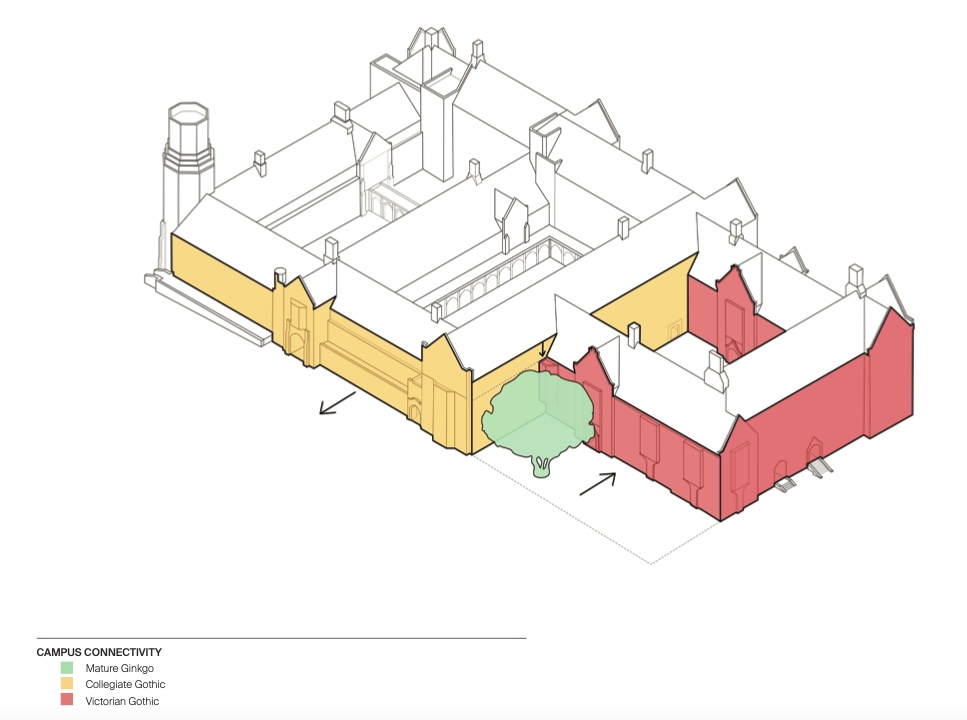

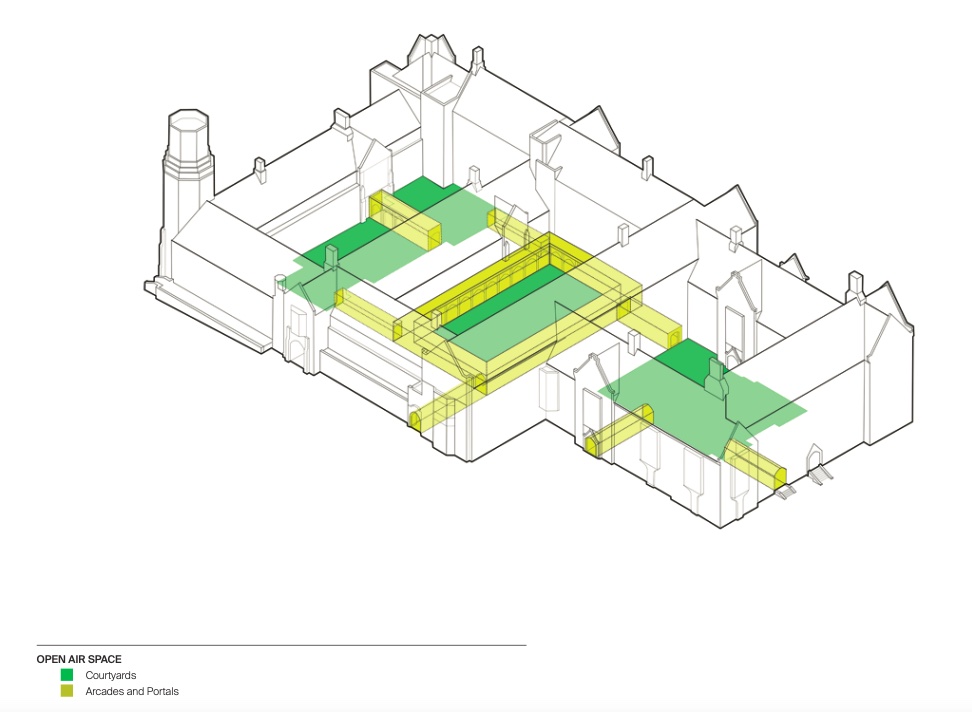

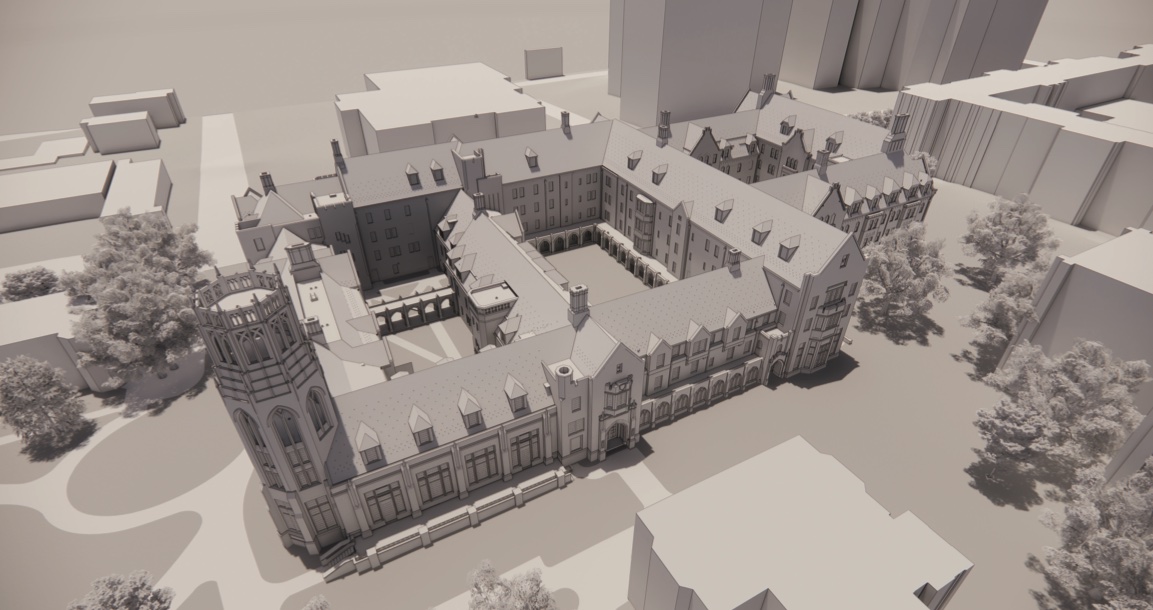

Kirkland Hall, the Victorian gothic symbol of the school, graces everything from the cover of university publications to football tickets and greatly informed the deep red brick facade design of the neighboring Ingram College building. More Collegiate Gothic elements of the Ingram College building, such as the different stones and 100-foot-tall belfry tower, were in direct response to the adjacent 1925 Alumni Hall. Designed by David M. Schwarz Architects and HASTINGS Architecture, E. Bronson Ingram College offers 220,000 square feet of living and learning environment for both faculty and students.

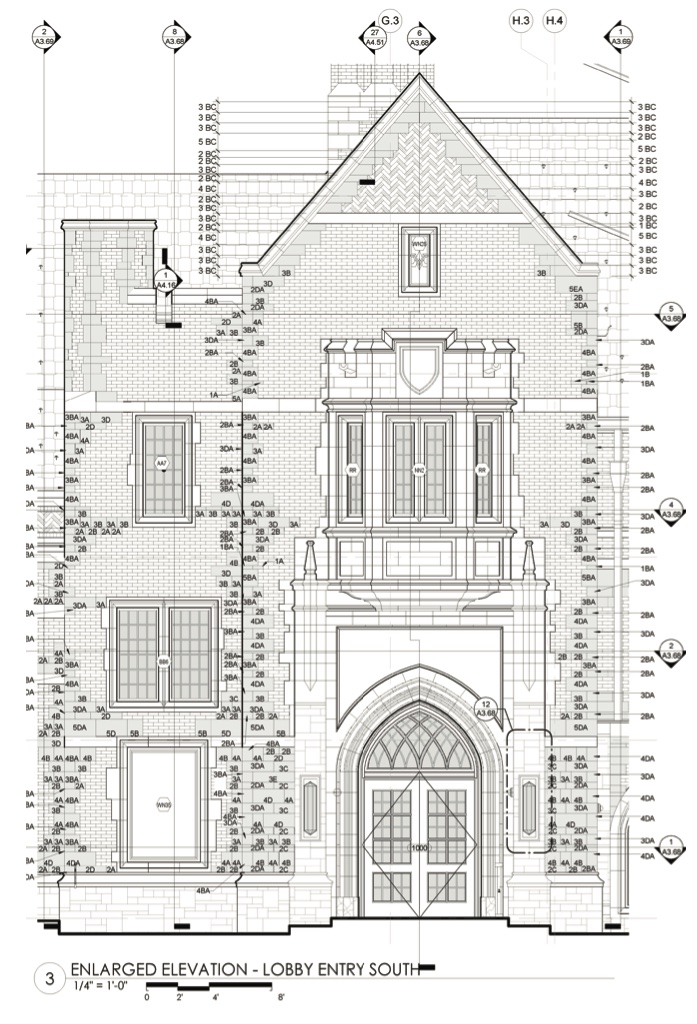

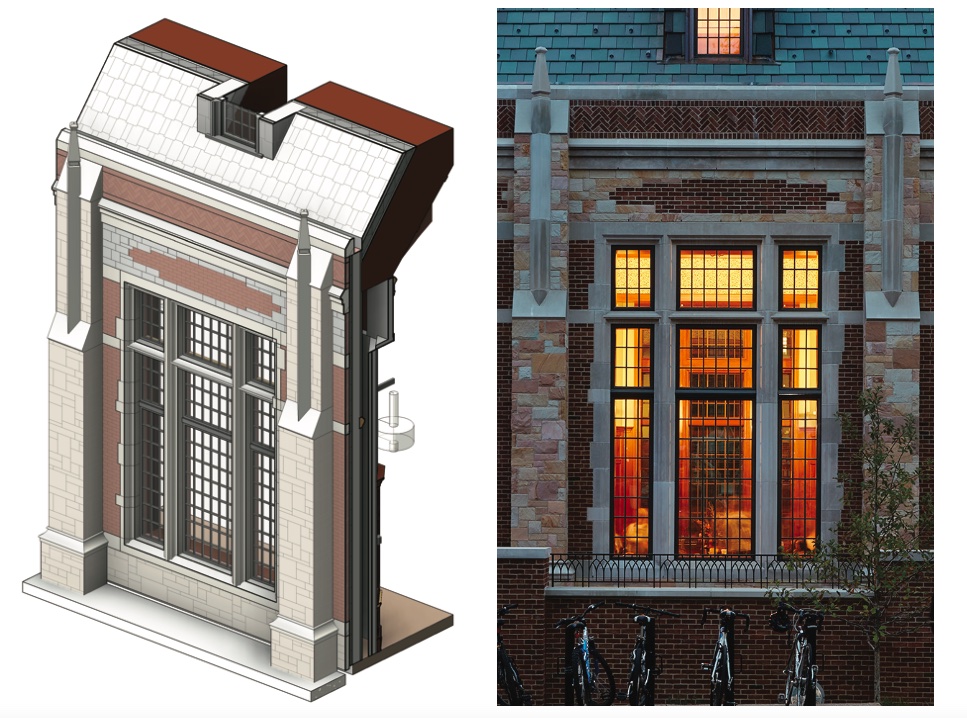

The new campus addition features a reinterpretation of the traditional modular brick used across Victorian gothic facades, while the Collegiate Gothic envelope integrates the brick with limestone and light-colored crab orchard stone accents, dubbed “sprinkles.” Traditionally, this kind of masonry was load-bearing, which required less coordination and planning than most modern structures. However, here the masonry is supported floor-by-floor by steel relief angles. This required the use of complicated and strategically located masonry expansion and building expansion joints, painstakingly placed to function without being visible and without creating the recognizable signatures common to traditional applications. Adding to the complexity, precise alignment from one building wing to another was required.

Early wall sections within a concrete frame were designed with a concrete masonry unit (CMU) infill, however, due to the budget and schedule, ultimately metal stud infill with glass mat gypsum substrate was used. “This move put additional pressure on the framing and additional support elements within the structure necessary for the brick and stone veneer. To support the masonry veneer, the structural engineering required horizontal steel relief angles at each floor level. These were located and detailed within the coursing of the overall facade, and slotted steel ‘knife’ supports offered the mason critical two-way adjustability when the angles were attached,” explained Paul Law, Associate Principal and Director of Quality Assurance at Hastings Architecture. The open-air tower at the southwest corner of the complex also required a steel skeleton to support the intricate stonework.

To further support the deceivingly lightweight facade, Ludowici clay tile roofing was utilized over a high-temperature underlayment and vented polyiso system. The polyiso insulation maximized the R-value at the roof while the CDX plywood facing beneath offered the stable nail surface required by the roof tiles.

HASTINGS Architecture coordinated carefully with the contractor, R.C. Mathews, and structural engineer EMC Structural Engineers, to ensure they could arrive at an authentically complex facade that also could facilitate LEED Gold certification, high-performance building automation, and energy-efficient systems. Given Nashville’s climate zone, the facade system uses vapor-permeable liquid air, water-resistive barriers, and mineral wool continuous insulation within the cavity.

The team built large on-site mockups to test not only these energy standards and aesthetic patterns but also to determine the selection of custom mortars and sealants. This allowed for a detailed study of the copper elements at the roof, and critical intersections of various materials used in the facade as well as artistry carving. HASTINGS’ unique kit-of-parts for the exterior elements utilized Revit families to coordinate the 62 window profiles and varying sizes of stones used across the 90 different window types. To reduce errors in quantifying, each individual stone family was built as a shared family and given a type of parameter to track counts and allow individual tagging in construction documents.

After 16 months of design and 26 months of construction, the E. Bronson Ingram College harkens to a long-standing history that plans to welcome students for just as many years to come in the future.