Commonwealth Avenue, snaking from the Boston Public Garden through the greater metropolitan area, is no stranger to significant cultural venues and institutional buildings. Boston University’s Joan & Edgar Booth Theatre and College of Fine Arts Production Center, by local firm Elkus Manfredi Architects, joins this assemblage with an angled glass curtainwall shrouded in a scrim of ultra-high-performance concrete (UHPC) and flanked by vertical strips of metal panels.

The 75,000-square-foot building rises to a height of approximately 57 feet and largely follows a rectangular massing. While the majority of elevations rise perpendicularly from the ground level, the north elevation is defined by a 42-foot-tall glass curtainwall tilted at a 14-degree angle. The glass panes, measuring 7-feet-by-14 feet, were structurally adhered on site and lifted into place using a custom steeling rigging system.

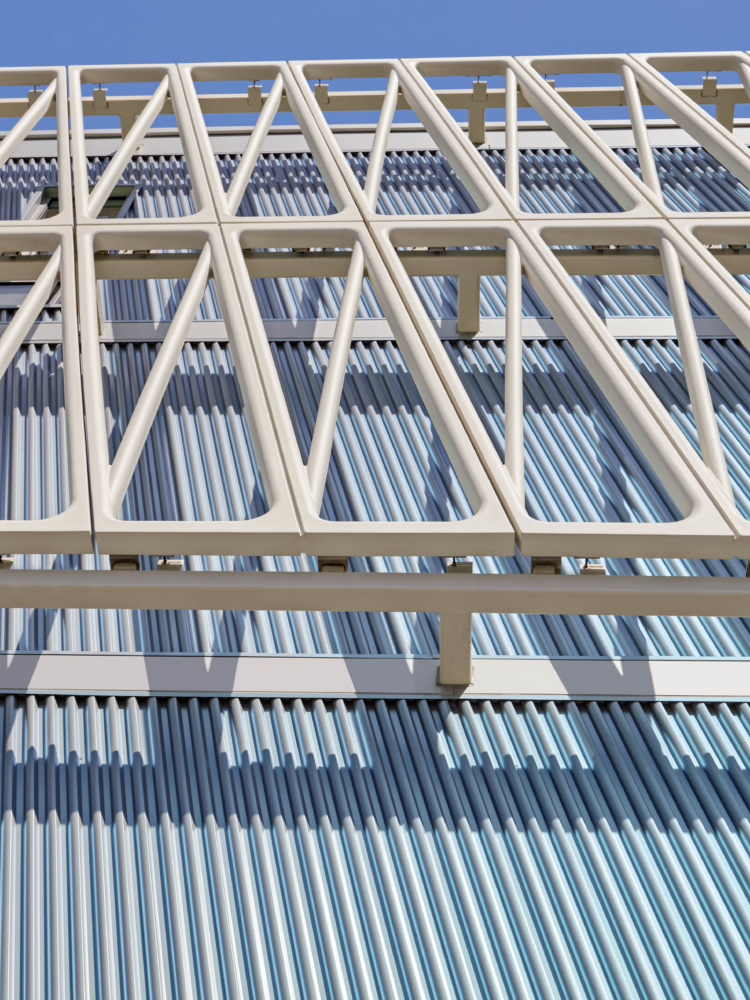

A scrim of UHPC panels frames the primary northern elevation and folds onto the east and west elevations, a design feature intended to evoke a proscenium screen shrouding the entrance of the theater. In total, there are 83 UHPC panels measuring 14-feet by 7-feet, each weighing approximately 1,600 pounds. Tubular steel outriggers, cantilevered from the slab edge and running horizontally, serve as a platform for the concrete panels.

For Beton, a Montreal-based fabricator, the project was a first in their production of ultra-thin concrete. “Not only does the color of the UHPC concrete tie the building into its immediate surroundings—including the sandstone former Cadillac dealership, a national landmark next door—the material can also take the desired form reminiscent of theatrical fabric, unlike stone,” said Elkus Manfredi Architects vice president Ross Cameron. “The engineered concrete-polymer material has three times the tensile strength of traditional concrete yet weighs half as much, so the design team pushed to use the material in these new ways, striving for ever thinner and delicate forms.”

Besides the entrance atrium, there are limited chances of fenestration across the rest of the building due to performance spaces within. For the remaining elevations, the design team opted for Ipe wood and aluminum siding. Produced by Centria, and treated with their Kolorshift PVDF, the aluminum panels reflect different colors depending on their exposure to sunlight—their character effectively morphs according to weather, time of day, and season. This dichroic effect is amplified along the northern corners of the east and west, where the aluminum panels were installed diagonally, producing a wave-like effect of color differentiation.

The relative formality of the south elevation, along Dummer Street, is a response to the immediately adjacent residential neighborhood. Throughout the design process, the design team met regularly with the surrounding community to address their concerns. The use of Ipe wood softens this elevation and links it materially to it wooden dropside neighbors, while louvered windows provide glimpses within.