Arnsberg is a small German city located northeast of the Cologne metropolitan region. The city is centered on the Ruhr and is surrounded by protected forested land, and largely survived the damage inflicted on other German cities during World War 2. Arising from this historical context is the Sauerland Museum expansion, one of the city’s most significant projects in years, constructed of self-supporting travertine cladding and designed by Bez + Kock Architekten.

The project is an extension of the preexisting Sauerland Museum, which is housed in the Landsberger Hof, a former palace constructed in 1605. Typical for the era and regional vernacular, the palace is composed of lime-washed masonry arranged according to classical symmetry and topped with a steeply pitched gable.

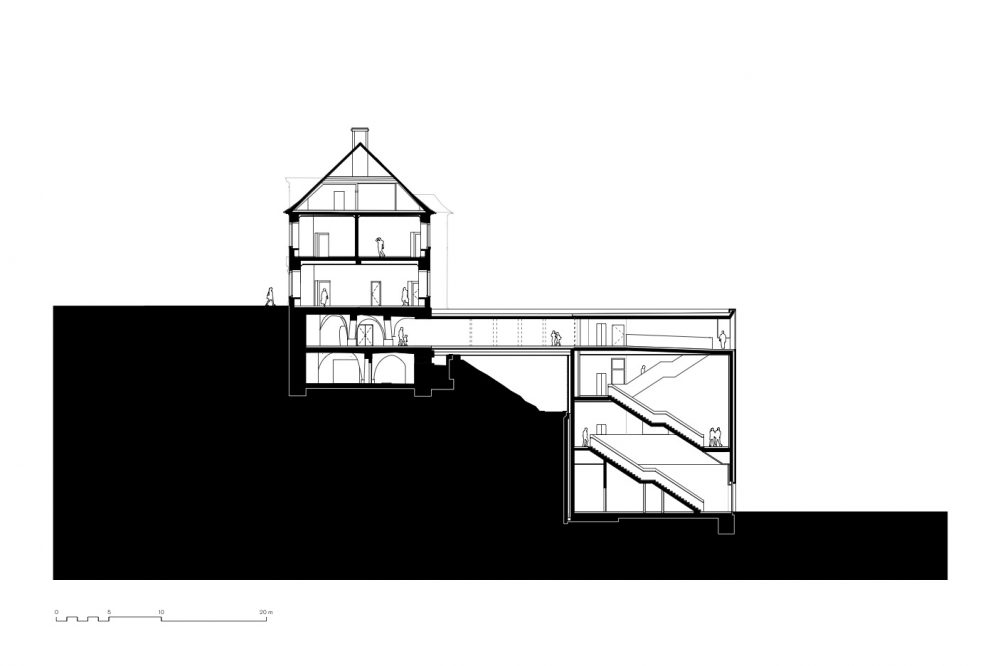

Bez + Kock’s extension is located at the bottom of a steeply pitched slope leading up to the palace—a challenging location in terms of urban planning and construction. The original concept of the extension called for constructing over the contours of the site, but was ultimately adapted at the request of the client into its finalized form of stepped massing which rises approximately 50 feet into a slender bridge linking the two structures. The facade is sheer and, due to the narrow mortar joints and select window openings, appears monolithic. Window openings, bar that on axis with the connect bridge, are canted from the rectilinear form to diffuse sunlight from the interior curatorial spaces.

For the original concept of the museum, the design team intended to use locally sourced Grauwacke sandstone, which is known for its dark heterogeneous coloring—a color palette that would have seamlessly blended with the adjacent retaining wall. However, this dark cast was found unsuitable for the standalone stature of the reoriented extension. In response, Bez + Kock opted for Gauinger travertine produced in the Swabian Alps.

While the project’s massing is distinctly contemporary and its facade is stripped of ornament, the masonry components are in part traditional in that they are self-supporting. “The pattern was developed in accordance with the technical requirements of all windows, doors and technical elements in the facade, and the lengths of the individual stones are random, which was a cost-saving decision,” said the design team. “To enhance the horizontality of the surfaces and tie together the individual elements, we specified that the vertical joints would be flush, while the horizontal joints are mortared.”