Boston’s Seaport District is no stranger to development; the 23-acre site lies east of the Fort Point Channel on the Inner Harbor, and over the last two decades has transformed from a largely barren deindustrialized waterfront to an effective extension of the city’s core. Pier 4, a 400,000-square-foot mixed-use project designed by local firm Elkus Manfredi Architects, is an exemplar of this trend and proposes an alternative to boxy glassed massing with staggered floors and eye-catching soffits of aluminum composite panels.

The project is located immediately adjacent to the HarborWalk and the Institute of Contemporary Art and is prominent from both an urban and visual standpoint. Considering its location, the city dictated that the bulk of the building’s ground floor be dedicated for public use—the lobby can be passed through by pedestrians and features a range of retail spaces. In keeping with the project’s public-facing manifesto, the primary entrance, in a particular flourish, is surrounded by a prismatic display of polished and reflective aluminum. From this base, the tower rises to a height of 13 stories.

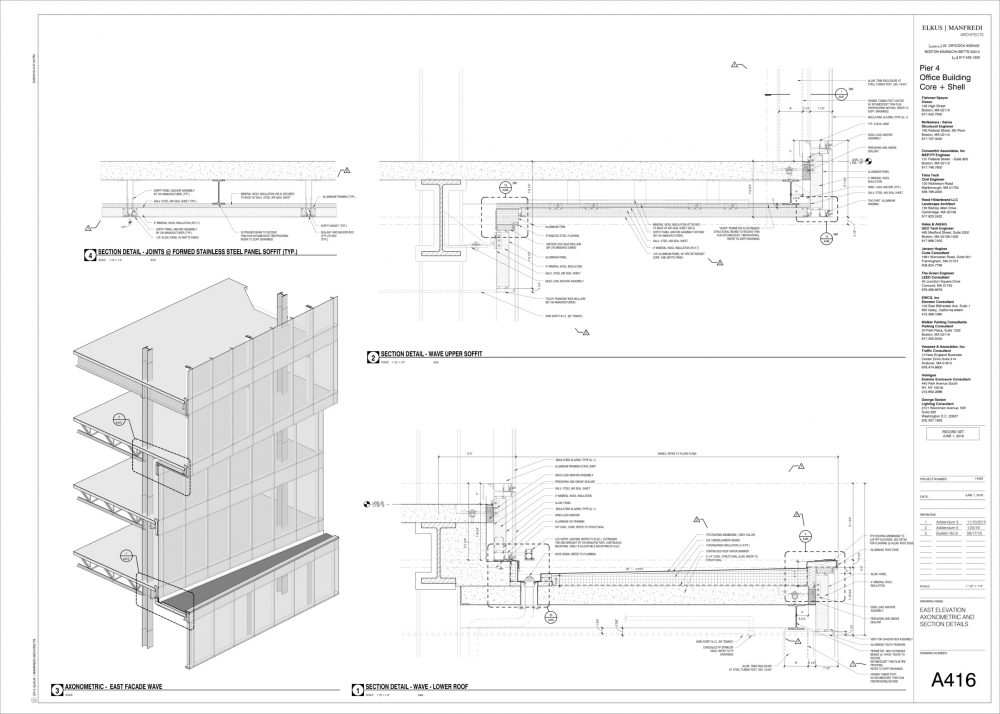

For the design team, there were two primary views that dictated the tower’s massing; that towards downtown Boston and the other facing the harbor. “The west facade, facing downtown Boston, has a more subdued gesture with a trapezoidal cut-out terrace,” said Elkus Manfredi Architects vice president Christian Galvao. “The east facade, facing Boston Harbor, has two-story undulating triangular moves that shift and slide between each other, creating a constant movement that changes throughout the day.”

Clad in high-end solar control 1 1/4″ insulated glass units produced by AGC Interpane, the project follows the standard erection and installation techniques of a unitized system. Each floor-to-floor unitized panel measure 5′ by 12’8″ and are divided by mullions and horizontal ‘kiss mullions’ at the slab edge. Ferguson Neudorf Glass handled the installation and fabrication of the facade, including the 1/8″ thick aluminum composite plates found at the soffit of each floor plate which are held by a custom-designed system of cantilevered beams.

According to Elkus Manfredi Architects, one of the greatest challenges of the project was ensuring its timely and seamless construction and completion. “The unitized curtain wall system could have no major delays during the erection of the pre-fabricated glazing panels and in-field waterproofing installations,” continued Christian Galvao. “The amount of detailing in the advance construction documents, shop drawing reviews, and performance mock-up testing were crucial to its success.”