Diller Scofidio + Renfro (DS+R)’s first skyscraper, 15 Hudson Yards, is now complete after four years of construction. The 88-story residential tower fuses the largest cold-warped glass curtain wall in North America with a louver and limestone base.

The tower is located on the southwestern flank of Hudson Yards‘s first phase located on 28 acres between 30th and 34th Streets, and 10th and 11th Avenues. One of the sites many towers, 15 Hudson Yards alone will enclose a whopping 980,000 square feet.

The 914-foot-tall project rises from a CNC-fabricated limestone base sourced from Carrara, Italy. According to the design team, parametric guidelines and 3-D modeling facilitated a seamless design-to-fabrication process for both the approximately 1800 stone panels and their steel support systems produced in Queens and New Jersey. The rear of each panel is studded with metal angles fastened to a network of bent plates attached to the steel support system.

The Shed, also designed by DS+R, adjoins the smooth limestone surface of 15 Hudson Yards along a diagonal seam defined by polished and formed steelwork by CIG Architecture. Incorporating the dynamic performance arts space into the base of the tower presented a number of mechanical and structural challenges for the design team. The 48.7-inch-wide modules all have both a glass and ventilation louver component. The designers varied the ratio of the two pieces parametrically to best ventilate interior mechanical equipment, with the widths of the louvers ranging from 4 to 31 inches.

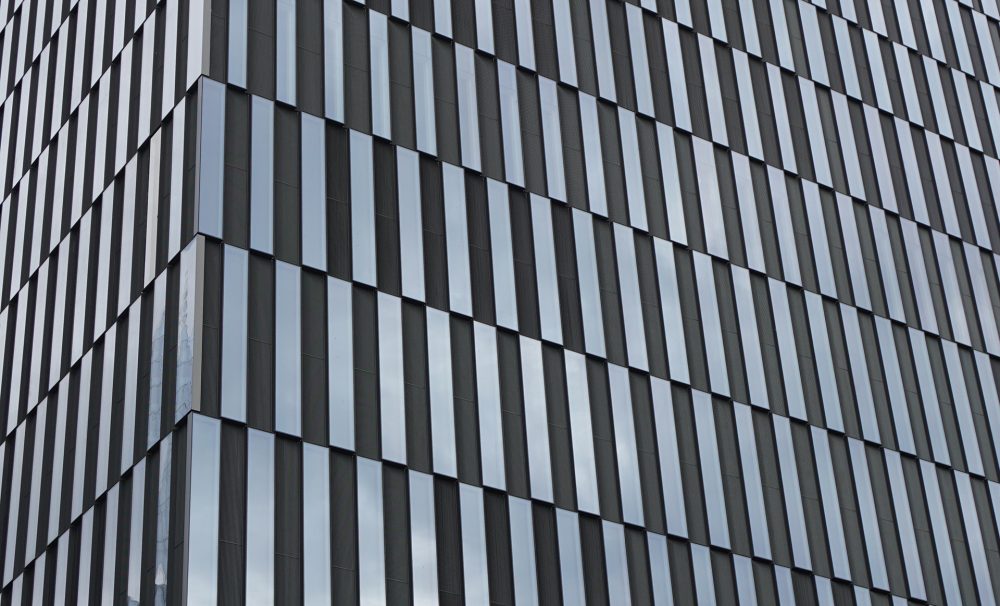

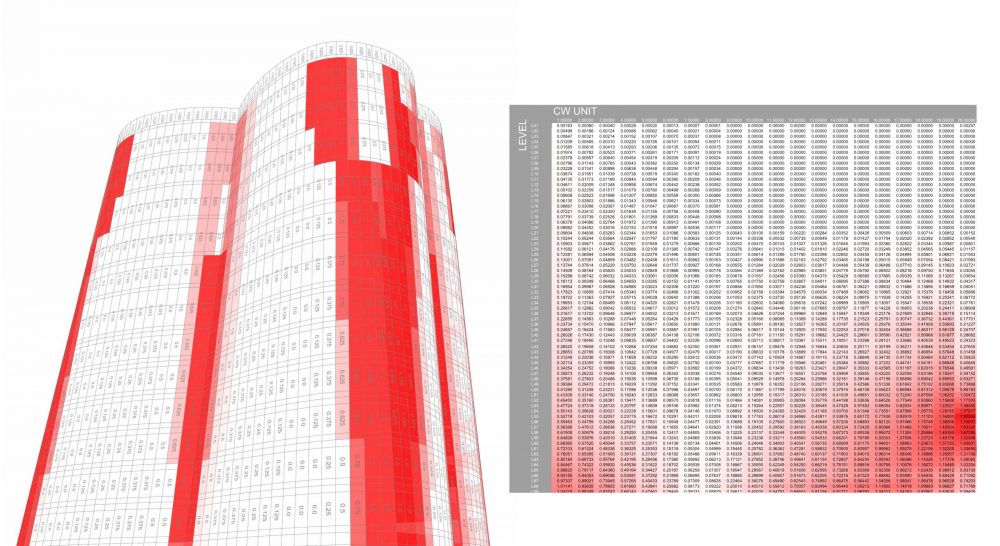

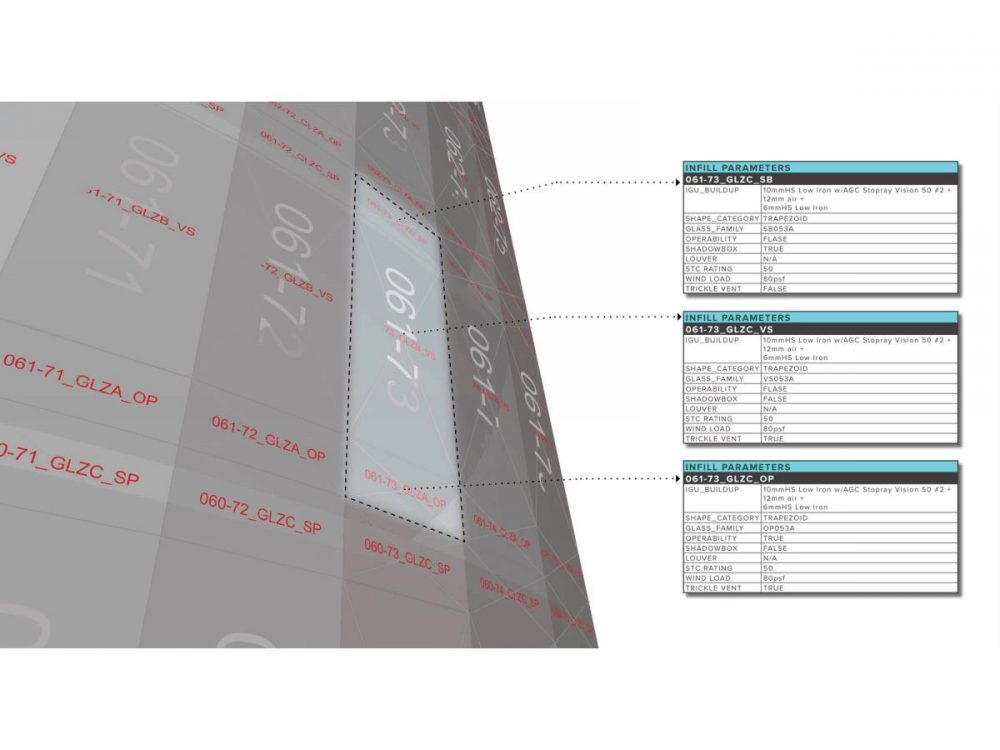

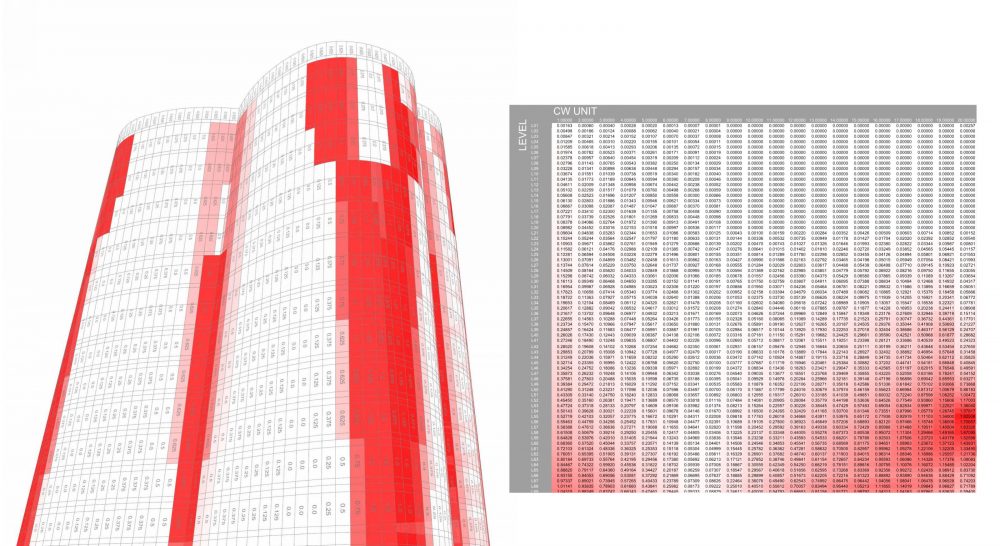

Beginning at the 20th story, the tower dramatically curves using a cold-warped unitized glass curtain wall system. The individual glazing units, produced by German manufacturer Interpane, were cold-warped on site. To warp the glass components, the panels were held in trapezoidal frames with silicone seal joints that anticipated the final form of the panels once they were bent into place. While early renderings of the project depicted 15 Hudson Yards with anatomical undulations, cost constraints and manufacturer warranties straightened the design into its current form.

“We worked very closely with curtain wall fabricators from concept through execution, and the tower’s form is a product of this close collaboration,” said facade consultant Neil Thelen. “Using a collaborative parametric approach, we were able to iterate and analyze the impact of the tower’s curved forms on critical parameters such as IGU cold-warping, aluminum extrusion die option, unique part and assembly reduction, gasket engagement, and window operation.”

Above the amenity spaces located roughly halfway up the tower—which are clad with glass mega panels—the facade’s curvature increases dramatically, effectively breaking into four turrets. The glass panels deflect up to 8 inches at the skyscraper’s summit.

Although the dimensions and material of the facade differ throughout the tower, the cladding all attaches to the structural frame with a similar technique.

“There are embedded plates in the slab edges to which faceplates are bolted with adjustable screws to align bearing points for each wall unit. Each curtain wall unit has a pair of load bearing hooks at the top where the dead load is transferred to the building structure from the hooks,” said DS+R project director John Newman. “It hangs from there and interlocks with a large, gasketted tongue-and-groove extrusion at the top of the unit below.”

In response to river-borne gusts, the facade is designed to withstand 100-year wind loads with a system of structural silicone profiles, mullions, and steel reinforcements for spans greater than twelve feet. Additionally, testing conducted by an independent lab determined the placement of supplemental-load bearing aluminum extrusions.