It is difficult to conjure a more challenging setting than Antarctica for the design and construction of structure suitable for habitation and scientific research. Designed by Brazilian architecture firm Estúdio 41, the recently completed Comandante Ferraz Station accomplishes just that with a sleek design to boot, and is clad with dark turquoise polyurethane sandwich panels.

The approximately 53,000-square-foot project is located on the Keller Penninsula, a rocky outcrop of King George Island—the island hosts a population of around 500 scientific researchers. The Comandante Ferraz Station replaces a preexisting base, which caught fire in 2012, and is something of an upgrade from what was a campus of souped-up shipping containers.

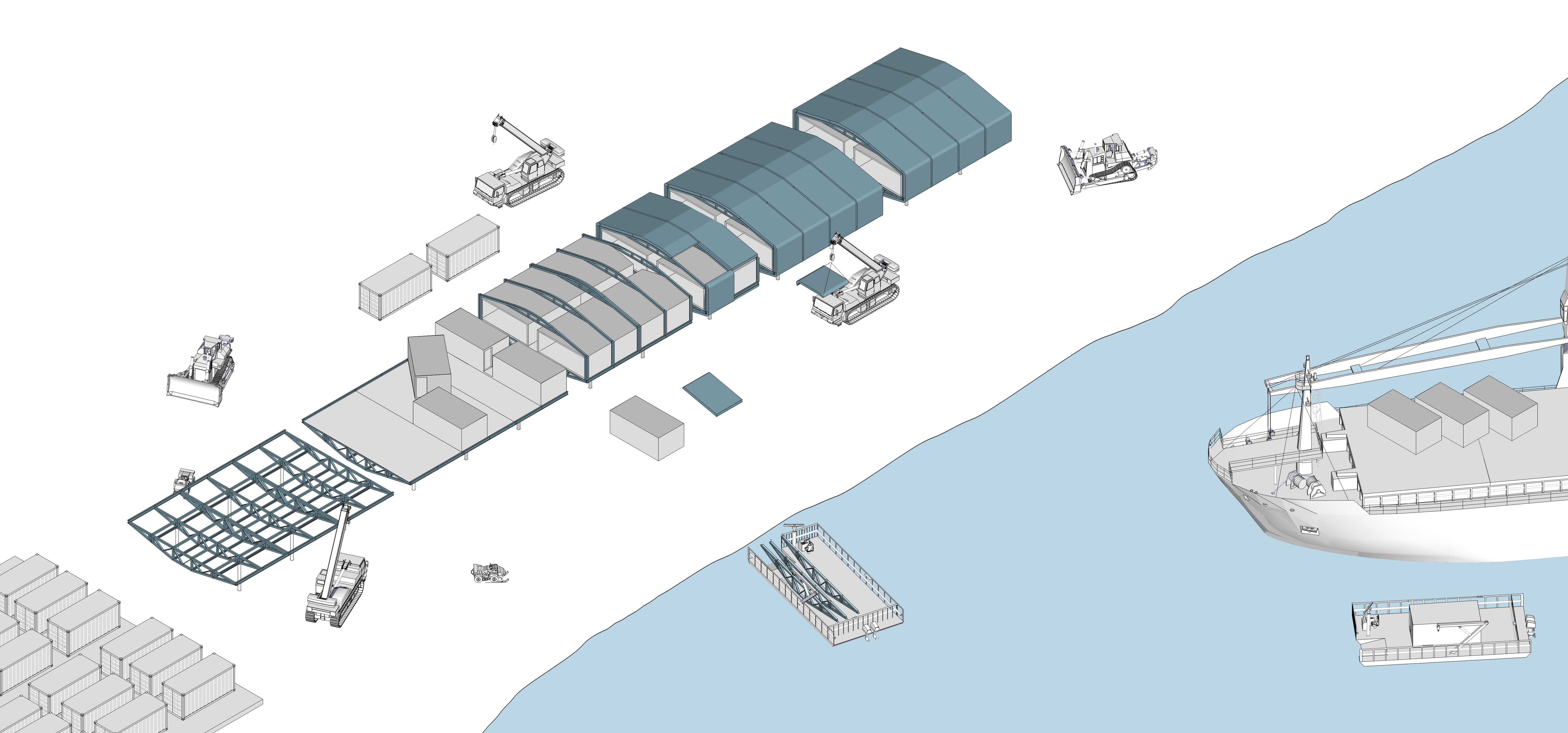

The Brazilian Navy commissioned an international competition just a year after the accident, and Estúdio 41’s proposal was selected for its consideration of the surrounding geography while offering state-of-the-art workspace. The new campus is centered on two core rectangular blocks lifted several feet off the ground by a system of steel pillars, which, in turn, support a grid of steel trusses and latticed and vertical braces for the roof. Unsurprisingly, insulation is key to the success of the station and is achieved with nearly nine-inch-thick polyurethane foam insulation sandwiched between galvanized and coated sheet steel panels held to the internal structure with stainless steel screws.

Thermal bridging is a common problem for any project, let alone one in Antarctica, and the design and engineering teams opted for Schöck’s Isokorb Type 22 Structural Thermal Breaks, which, as load-bearing thermal insulation elements, could accommodate the project’s extensive axial and shear forces.

The remote setting and Artic climate posed an additional set of challenges for the project; construction started in 2015 but could only take place during the relatively mild summer months and the prefabricated components had to shipped in segments. CEICE, a Chinese construction firm, managed the fabrication and installation of the project, which was dissembled prior to shipment. The facility was inaugurated by the Brazilian government on January 14, 2020, and began operations this summer.