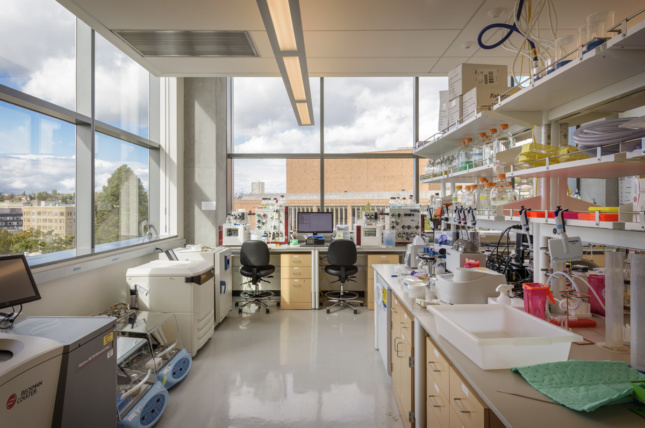

Six years after the University of Washington opened its 90,000-square-foot Molecular Engineering and Sciences Building (MolES), a new addition, the Nano Engineering and Sciences Building (NanoES), has nearly doubled the size of the complex located at the center of the University of Washington (UW) Seattle-based campus. The Seattle offices of Zimmer Gunsul Frasca Architects LLP (ZGF) programmed and designed the two-phased MolES and NanoES buildings, which together provide 160,000 square feet of research space in the field of interdisciplinary molecular engineering considered critical for ensuring future economic, environmental and medical health worldwide. NanoES features unique fabrication and characterization equipment to measure and manipulate molecules at the nanoscale. This second phase relies on custom-engineered products from Wausau Window and Wall Systems to achieve more stringent building and energy codes than were initially in place for phase one.

An intensive three-day series of design charrettes brought together the owner, architects, general construction company, curtain wall manufacturer, and glass installer at the onset of the project. Based on the charrettes’ targeted value, design goals, code requirements and LEED Silver criteria, Wausau’s four-sided structurally glazed (4-SSG) unitized curtainwall system was selected for the project.

- Facade Manufacturer

Viracon (glass fabricator); Tubelite Inc.(entrance systems); Wausau Window and Wall Systems (glazing and shading systems) - Architects

Zimmer Gunsul Frasca Architects LLP (ZGF) - Facade Installer

Herzog Glass, Inc. (glazing); Linetec (glazing, entrance, and shading systems finisher); Hoffman Construction Company (general contractor) - Facade Consultants

University of Washington, Capital Projects Office (Owner) - Location

Seattle, WA - Date of Completion

2017 - System

Structurally glazed, unitized curtainwall - Products

INvision 8250i-HRX Series 4-SSG curtainwall with 4250z Series zero sightline, project-out awning windows (by Wausau); VNE-63 solar-control, RoomSide Low-E, argon-filled, insulating glass (by Viracon); ClearStory exterior sun shades (by Wausau); Therml Block entrances with thermal strut (by Tubelite); 70 percent polyvinylidene fluoride (PVDF) resin-based liquid paint (by Linetec)

“The 4-SSG unitized curtainwall was glazed and sealed in Wausau’s factory-controlled conditions. This achieved the targeted designed performance and industry-leading, 10-year warranty required for the project and for the UW campus facility plan,” explained Brad Glauser, Wausau’s Northwest Territory manager. “The units were built one lite wide by one floor tall, with interlocking vertical mullions that aligned with the adjacent rain screen’s stone façade, thus creating a true continuous thermal envelope.”

One benefit of ZGF’s integrated design approach was improved communication, which led to a reduction of Addenda, Requests For Information and Architect’s Supplemental Instructions submitted during the pre-construction and construction process. The resulting assembly of the unitized system was installed and enclosed within five weeks. Some of the curtainwall units on NanoES were up to 16 feet tall. To carefully install each unit, lift equipment hoisted each unit onto embeds at face-of-slab, where they were anchored with J-Clips. In total, more than 22,000 square feet of curtainwall were installed on the project.

Integrated within the curtainwall are zero sightline project-out awning windows with both manual and motorized operators. In certain areas, windows are programmed to automatically open at night to provide natural ventilation and lessen energy load demands on the HVAC system.

Complementing the high-performance curtainwall and window systems, custom, 6-inch-deep aluminum fins at vertical members and 24-inch-deep exterior sun shades were integrated into the building envelope. ZGF designed customized shadow boxes, similar to those on MolES, to add visual depth to the assembly. These elements are all protected with a two-coat “Silver Shadow” mica coating that matches the neighboring MoIES building.

Linetec manufactures the resin-based liquid paint through a process that captures the materials volatile organic compounds (VOC) content using a 100 percent air capture system and safely destroys the VOCs with a regenerative thermal oxidizer. Linetec then reuses its heat energy byproduct to improve process energy efficiency. This process of reuse is completed before the material exits the paint line.

“The combination of durably finished, 4-SSG unitized curtainwall and high-performance glass achieved UW’s requirements,” summarizes Glauser. “We exceeded the national forerunning Seattle Energy Codes, as well as UW’s energy-efficiency goals with low solar heat gain coefficient, low U-Factor and high condensation resistance. At the same time, high visible light transmittance was maintained, providing occupants with access to daylight, a transparent connection to views and interior comfort. We stayed ahead of schedule and within budget. In my book, this definitely is a success story.”

Elaborating on this success in the Daily Journal of Commerce, ZGF’s associate partner Nicole Cooper, AIA, concluded, “The strong partnership between UW and the design team, as well as a commitment to sustainability, brings the Molecular Engineering and Sciences Building and the Nano Engineering and Sciences Building together to create one high-performance building that fosters a collaborative research environment for years to come.”