The Safdie Architects–designed Jewel Changi Airport is a 144,000-square-foot toroidal-shaped glass-and-steel pavilion looping around the world’s tallest indoor waterfall. After four years of construction, the $1.3 billion project opened its doors in April 2019 as a bid to deliver a “paradise garden” amid the cacophony of Singapore’s largest airport.

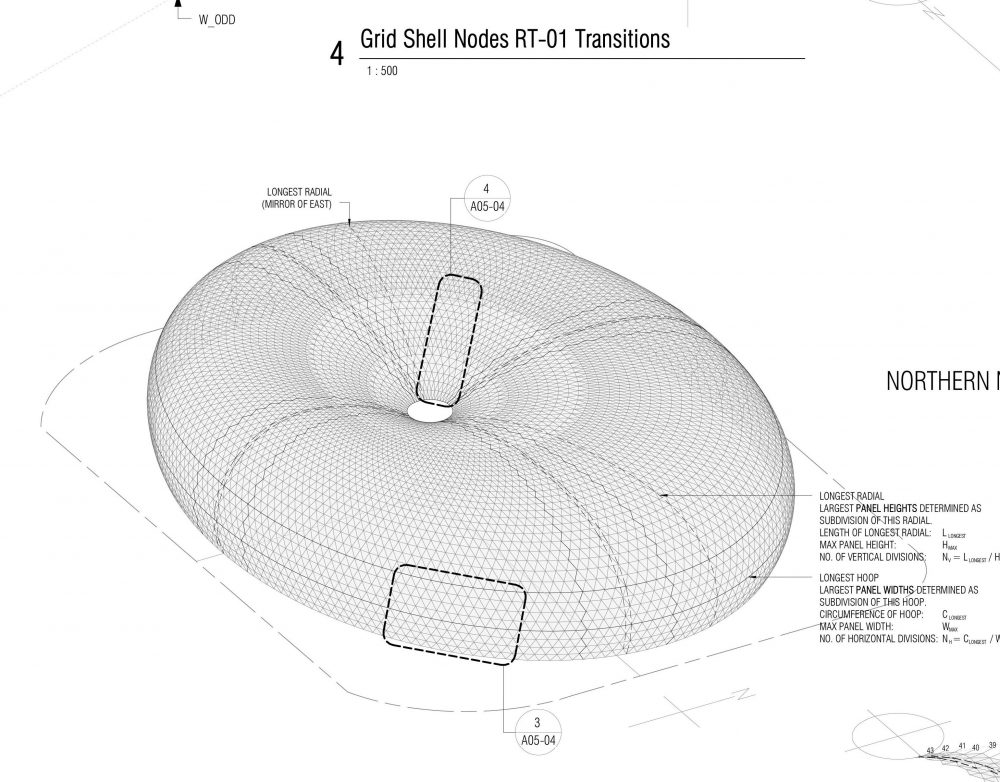

The structural system of the canopy is based on a highly complex stick-and-node mesh fabricated with over 50,000 distinct components assembled piece by piece on-site. The roof spans approximately 675 feet at its longest point and 510 feet at its widest. In total, the steel mesh weighs a colossal 6,000 tons.

From above, the pavilion’s layout looks symmetrical, with many identical glass panels. This is not the case. “The design of the roof is a single-layer add-on system composed of 9,000 custom cut—no two panels are the same—double-glazed panels positioned over the triangulated steel diagrid structure,” said Safdie Architects principal Jaron Lubin. “The double-glazed panel sizes were determined to a maximum dimension of 8.5 feet measured diagonally, which was the size found commonly among several major suppliers.”

The project is wrapped with Vitro Architectural Glass’s Low-E Solarban glass, while Vitro’s high-visibility Starphire Ultra-Clear is used for the interior’s pedestrian bridges. By using Low-E glass, the project is slated to receive a platinum rating from Singapore’s GreenMark program.

Although the mechanics of the project are remarkably complex, Safdie Architects developed a design-to-construction methodology to ensure the timely completion of the pavilion. “The entire system, including glass panels, steel members, and the custom-shaped solid steel nodes, was fabricated directly from the design team’s computer model by CNC robots,” said Lubin. “The components were produced off-site and then shipped to Singapore in containers. Special labels with scan codes were used on all the components to assist in locating their final position in the building.”

The centrally located Rainwater Vortex, the massive waterfall around an oculus approximately 33 feet in diameter, is the product of collaboration with BuroHappold Engineering and water-feature design firm WET Design. The oculus is topped with an ETFE cushion while a custom-designed circular valve controls water flow between a narrow gap in the glass facade’s surface.